TDTG Bucket Elevator

TDTG Bucket elevator features:

1. High quality steel plate;

2. The Bucket Elevator uses advanced equipment to bent and weld;

3. No dust leakage thanks to good sealing performance;

4. Good wear resistance thanks to high molecular polyethylene bucket;

5. Uses high-intensity bucket flat belt, low elongation;

6. High-strength bolted joint.

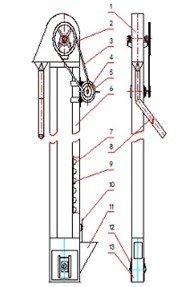

1. Discharging hoper

2. Big belt wheel

3. Triangular belt

4. Motor belt wheel

5. Motor

6. Return pipe

7. Hopper belt

8. Outlet

9. Materials hopper

10. Adjustment lever damper

11. Materials inlet

12. Adjustable screw

13. Materials bin

Materials enter the bin through the inlet and are elevated to discharger by the hopper in the conveyor;then jump and fall into outlet by centrifugal force and gravity.

Bucket elevator functional description:

The bucket elevator is ideal for use as a distributing elevator.

Floury products as well as bulk materials such as grain and flours can be handled in vertical or upward inclined more than 70 degree direction.

The bucket elevator features compact structure, stable operation, low noise, high efficiency, and convenient operation and maintenance.

Technical parameter of bucket elevator:

|

Model |

TDTG20/09 |

TDTG20/11 |

TDTG20/13 |

|

Item |

|||

|

(t/h) |

2 |

4 |

6 |

|

Delivery value |

|||

|

main wheel speed(m/s) |

2.5 |

2.7 |

1.26 |

|

main wheel diameter(mm) |

190 |

190 |

190 |

|

winnowing pan space(mm) |

176 |

182 |

182 |

|

power |

0.55 |

0.75KW |

1.1KW |

|

size(l×w×h)mm |

910×200×(765+X) |

1100×322×(1240+X) |

1220×510×(1550+X) |

|

(Note: X means nominal height) |

|||

|

mounting hole size |

142×142×Φ13 |

550×170×Φ21 |

570×Φ18 |

100T/Day Corn Grits and Flour Milling Plant in Tanzania

100T/Day Corn Grits and Flour Milling Plant in Tanzania