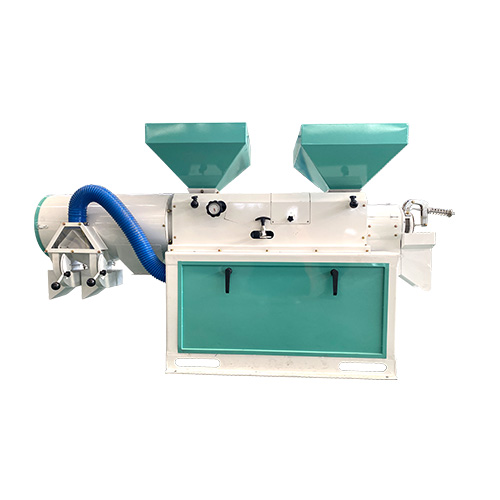

HX Pneumatic Corn Flour Grinding Machine

Working principle and features of corn flour grinding machine:

With breaking, cutting, hulling, rubbing of the material, the effect of grinding is achieved. It depends on one pair of opposite differential rotation to peel materials, extracting the endosperm and milling it into flour.

1. Pneumatic corn mill grinder has electrostatic spraying surface, bright color, elegant design, and luxurious appearance;

2. Automatic pressure control can be controlled individually or remotely by computer, high degree of automation;

3. In addition to pneumatic clutch, electromagnetic clutch can also be applied. Small size, low cost, easy to install, reliable performance;

4. The eccentric structured grinding roller is an independent self sustaining system and well shock absorbed;

5. Flat grinding roller set, the material is easy to enter the grinding chamber, efficient, convenient to maintain;

6. Synchronous rotation roller, smoothly operated, low noise, safe and environmentally protected;

7. The centre of the pneumatic corn grinding machine with negative pressure suction device can improve feeding status, lower temperature of the material;

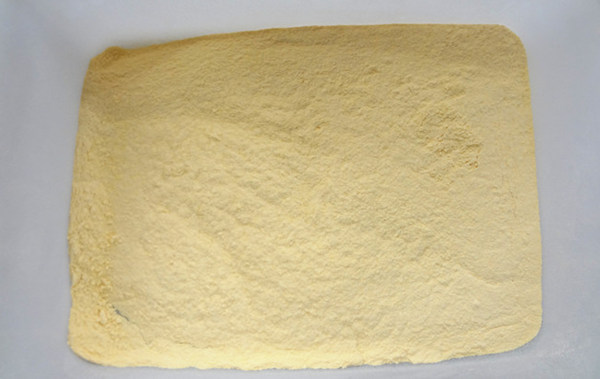

8. Finished products of grits, flour in uniform particle size, excellent quality, and large output.

End products of corn flour grinding machine:

Technical parameter of pneumatic corn grinding machine:

|

Model |

Yield |

Power |

Spindle Speed(r/Min) |

Weight |

Outline Size |

|

(T/H) |

(KW) |

(kg) |

(MM) |

||

|

HX125/25 |

2.5-3 |

30-5.5 |

450-600 |

4100 |

2072×1490×1920 |

100T/Day Corn Grits and Flour Milling Plant in Tanzania

100T/Day Corn Grits and Flour Milling Plant in Tanzania