Corn Grits and Flour Production Line with Dry Method

Corn Grits and Flour Production Line with Dry Method

Corn grits and flour production line adopts excellent automation solution. It can furthest reduce labor cost and production cost. The professional grain processing technology designers and commissioning engineers team can ensure the advanced technology, which can not only reduce energy consumption, but also reduce the influence to end products by impurities, dust and bran. Each product yield rate and products quality reaches or surpasses the national standard and this strengthens the market competition.

The whole corn grits and flour production line has the features of advanced technology, superior quality, strong specificity, reasonable layout, low energy consumption and so on. It is widely used in food enterprises, sugar enterprises and beer enterprises. And the core equipments have won the national patents.

Technological process of corn grits and flour production line:

1. Raw grain cleaning section: one screening, one stone removing, one magnetic separation. Equipped with winnowing system, it can remove the big and small impurities.

2. Peeling and degerming section: it adopts the process of twice peeling, once polishing, twice screening and once fine section.

1) Twice peeling, once polishing can ensure effective peeling and germ removing, and separates the flour and bran by air suction system.

2)Screening: it separates the material according to sizes and quality.

3)Fine selection: according to different gravity, it separates the bran and broken germs from the material by the joint action of cowl flap and airflow.

3.Corn grits section: it adopts the technology of fine grits making, flour brushing, screening classifying and suspending.

1)Corn fine grits:it smashes the material into grits and grinds the albumen with small hardness into fine powder.

2)Flour brushing:it separates the white flour from the material. 3)Screening:it classifies the material according to sizes.

4)Suspension: it separates the small bran from the grits by airflow according to different gravity.

4.Flour milling section:it adopts the technology of several times of grinding and screening.

1)Grinding: the material enters into the grinder and is ground into fine flour.

2) Screening: it separate the fine powder from the material.

5. Measuring and packaging section: the warehouse can reduce amount of labor. The measuring package can adopts manual method or electrical method.

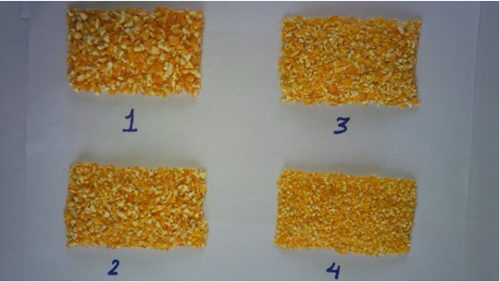

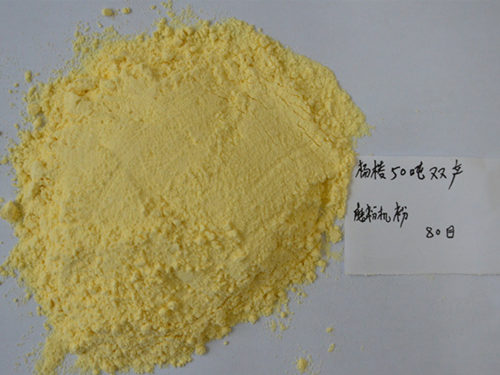

End products of corn grits and flour production line:

grade corn grits, grade corn flour.

Corn grits and flour prooduction line technical index:

1.End products: corn grits, corn flour and corn bran.

2.Yield rate: grade corn grits, grade corn flour 25-30%. Corn grits and corn flour total yield rate: 75~80%。

3.End products index:

A. Corn flour fineness:40-200 meshes(the flour fineness is adjustable)

B. Sand content:<0.02%

C. Magnetic metal content:<0.003/kg

D. Moisture:storage type 13.5-14.5%

E. Fat content:0.5—1%

F. Appearance and taste:even granularity, golden color, smooth kernels, fine powder, pure and natural taste.

Core equipments:

vibrating screen, classifying destoner, air blower, air suction duct, degerminator, germ extraction machine, polishing machine and flat sieve.

Corn grits and flour production line technology features:

1. It reduces equipment input in grain dampening and end products drying compared to the wet method technology.

2. Corn dry method processing technology makes the processing more sanitary and cleaner.

3. It reduces loss of albumen in peeling section.

100T/Day Corn Grits and Flour Milling Plant in Tanzania

100T/Day Corn Grits and Flour Milling Plant in Tanzania