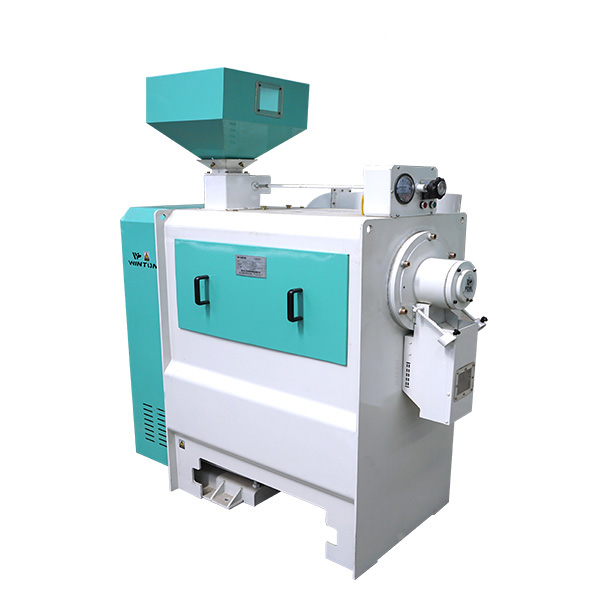

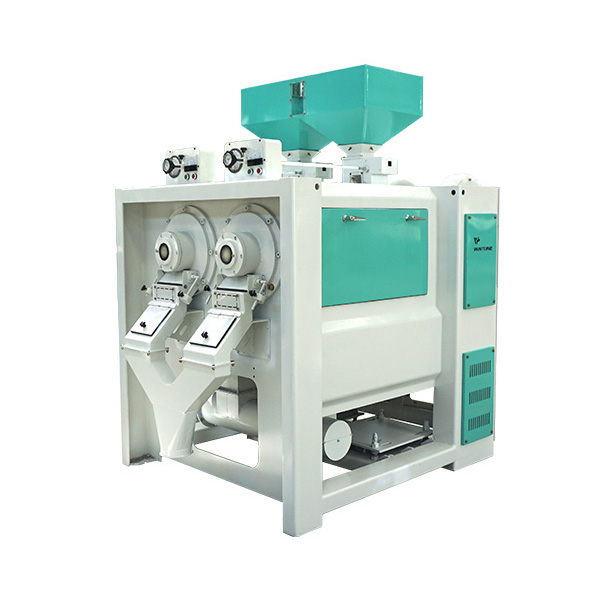

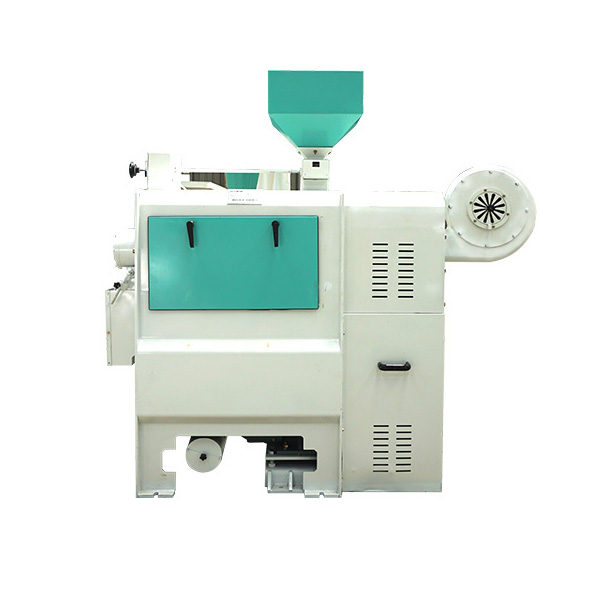

MTPS Series Corn Bran Removing Machine

MTPS series corn bran removing machine is the newly designed corn peeling equipment based on wide market research, customers’ opinion and various corn peeling machines advantages. It is designed after repeated trials. It is used as the supporting equipment in corn processing technology or as the single equipment. Letter A means external air blower. Letter B means internally installed air blower.

MTPS series corn bran removing machine has multi-functions. It adopts emery roll structure, which almost has no breakage to grain endosperm. It is usually used in corn peeling, wheat peeling, soybean peeling, mung bean peeling and sorghum peeling. It mainly consists of feeding mechanism, spiral propeller, peeling chamber, emery roller, transmission mechanism, discharging device and dust remover.

MTPS series corn bran removing machine utilizes high-speed rotating emery blade to cut and rub the corn bran and damage the bonding strength between the corn and the endosperm and the germ so as to make the corn bran, wheat bran or bean bran separated. It can also separate the corn germs and black spots during peeling process. The internally installed effective air draft chamber can collect the bran from the peeling process.

Features:

1. The internally installed air draft and dust removing system ensures the best sanitation condition.

2. Easy operation and maintenance, quick-replaceable sieve plate and other accessories, durable emery roll.

3. Even quality of the end products, multi-adjusting methods, reliable quality.

4. Moderate peeling process. Low grain consumption in peeling process.

5. Also suitable for dry method processing technology, which is more sanitary than wet method.

End Products of corn bran removing machine:

Corn bran removing machine technology parameter:

|

Model

|

Emery Roll

Diameter (mm)

|

Emery Roll Length

(mm)

|

Spindle Speed

(r/min)

|

Yield

(t/h)

|

Power

(kw)

|

Air Volume

(m³/h)

|

Size

(L*W*H)

(mm)

|

|

MTPS-18Y/A

|

Φ180

|

660

|

1300

|

1~1.5

|

22

|

|

1370×700×1900

|

|

MTPS-18Y/B

|

Φ180

|

660

|

1300

|

1~1.5

|

22

|

1500-1800

|

1410×1220×2030

|

|

MTPS-25Y/A

|

Φ240

|

660

|

1050

|

2.5-3.5

|

30

|

|

1515×660×2100

|

|

MTPS-25Y/B

|

Φ240

|

660

|

1050

|

2.5-3.5

|

30

|

1800-2100

|

1515×1220×2100

|

|

MTPS-30Y/A

|

Φ300

|

800

|

850

|

4-6

|

37-45

|

|

1690×710×2180

|

100T/Day Corn Grits and Flour Milling Plant in Tanzania

100T/Day Corn Grits and Flour Milling Plant in Tanzania