High Fructose Corn Syrup Production Line

High fructose corn syrup introduction:

High fructose corn syrup is called HFCS for short. The saccharified liquid from enzymic method saccharified starch isomerizes part of glucose into fructose through the isomerization effect by glucose isomerase. It is a kind of mixing syrup which consists of glucose and fructose.

High fructose corn syrup can replace cane sugar. Just like cane sugar, it can be widely applied in food and beverage industry. Especially in beverage industry, it has better flavor and taste and lower price than cane sugar. Its usage has outstanding advantages in food and beverage industry.

Technology introduction for high fructose corn syrup production line:

Dry method low fat corn flour—first, we process corn with dry method by peeling, germ extracting, fat and protein removing. The whole process doesn’t touch water, and has no sewage discharge. It processes corn albumen into low fat corn flour with 70-80 meshes, and then can reach the technology requirements for producing high fructose corn syrup.

After size mixing to the suitable concentration, the low fat corn flour enters into the section of liquidation spraying. After high temperature liquidation, under the catalysis action by amylase, the seriflux with starch is converted into dextrin. Saccharifying enzyme can catalyze dextrin into glucose. Glucose can form fructose by isomerization of glucose isomerase. To get high fructose syrup with higher sweetness, we usually separate the glucose from the mixture , make it have repeated isomerization and form fructose so as to improve fructose content in the mixing syrup.

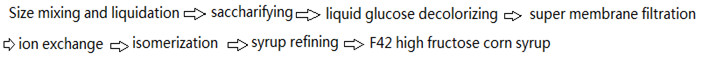

Technological process:

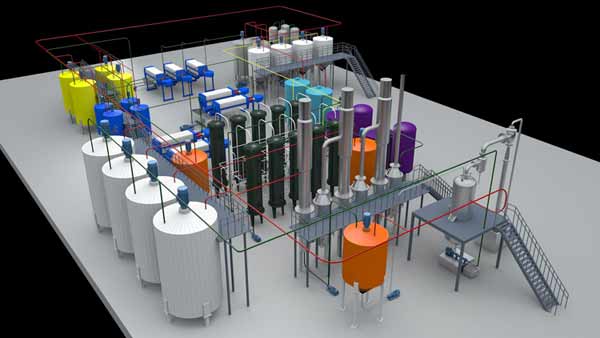

Core equipments:

High temperature ejector, bundle dryer, ion exchange column, second effect evaporating tower, candle filter, wet mill.

Technical features:

1. It adopts high temperature liquefying enzyme and two sections of spraying and liquidation technology. It controls the temperature by segmentation. It damages enzyme activity by high temperature to make enough starch liquefacation and complete albuminous degeneration without retrogradation. DE value is controlled 10-17%,and it has high starch yield rate.

2. It adopts flash vaporization and separates starch and the bran under high temperature. More than 90% of protein, fat and liquid glucose is completely separated.

3. Twice reverse-flow active carbon decoloration technology has long time of absorption and bleaching. It has strong absorption capacity for liquid glucose, residual fat, color and ash after layer filtering. It also has strong removing ability to liquid glucose organic impurity, which can furthest reduce the impact on the liquid glucose by protein fat color to ensure end products color and warranty period.

4. Second level ion exchange column and liquid glucose refining technology, removes low fat corn flour ash content sufficiently, raises the temperature for sugaring off and reduces discoloration problem.

5. There has Residual heat recovery design for the water and gas of the whole production line. The liquidation secondary steam recycle, ion exchange and water replacement, plate in exchange for water and evaporation condensation water recycle can save energy and reduce cost.

6. There has no wastewater discharge. The environmental protection cost is low and it conforms to the national industry policy.

7. The total investment is only 1/3 of the traditional wet method.

We provide you with whole set of energy-saving starch sugar design plan:

We can offer individualized design for different industries, different customers and different needs.

We supply automatic control system:

The advanced technology is the guarantee for high quality products. Continuous and stable production can reduce production cost.

We supply engineering installation, debugging and technical training:

When the equipments pass the strict quality test, our professional engineers will install, debug and train related workers on scene to make the project reach design requirements and normal running.

Our main research areas:

High fructose corn syrup

Malt syrup

Corn glucose syrup

100T/Day Corn Grits and Flour Milling Plant in Tanzania

100T/Day Corn Grits and Flour Milling Plant in Tanzania